This ISO 14409 specifies the terms and definitions, classification, materials and dimensions, test items and methods for air bags to be used for launching a vessel. It also specifies issues such as marking, documentation, packaging, transport, storage and so on.

This International Standard is intended for designing, manufacturing, testing and accepting air bags that are made of synthetic-tire-cord reinforcement layers.

Cited ISO standards by ISO 14409

ISO 34-1, Rubber, vulcanized or thermoplastic — Determination of tear strength — Part 1: Trouser, angle and crescent test pieces

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 815-1, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 1: At ambient or elevated temperatures

ISO 1431-1, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 1: Static and dynamic strain testing

ISO 7619-1, Rubber, vulcanized or thermoplastic — Determination of indentation hardness — Part 1: Durometer method (Shore hardness)

Item 4 (ISO 14409) Classification of ship launching airbags

This standard categorizes airbags according to their bearing capacity, per meter in length: QP means ordinary airbags with less than 6 reinforcement layers (cord rubber layers). QG means high performance airbags with 6 reinforcement layers (cord rubber layers).

Anyway ISO 14409 doesn’t literally indicate airbags with more than 6 reinforcement layers belong to QG type also. With more reinforcement layers, airbag will have higher bearing capacity. According the principle of airbag classification of ISO 14409, airbags with more than 6 reinforcement layers should belong to QG type.

Item 5 (ISO 14409) Material and dimensions of ship launching airbags

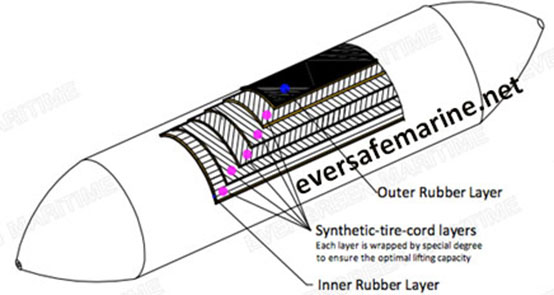

In the standard iso 14409, material for Ship launching airbag production is described as: An air bag is to be constructed of an outer rubber layer, one or more synthetic-tire-cord layers, and an inner rubber layer. All materials shall be vulcanized firmly.

The reasons to list inner layers, outer layer and synthetic-tire-cord layers separately are: they have different functions and made of different material. Inner rubber layer for ship launching airbags is designed to have good airtightness performance, normally made of EPDM, NBR and NR rubber. Outer rubber layer needs to withstand abrasion and puncture, thus has some functional chemical and reinforcement material. Different manufactures have different designs for the outer layer of airbags, the rubbers formula and rubber contents decide airbag cost and the performance, life span as well.

Insight of airbag structure

The synthetic-tire-cord layers are compound of rubber and nylon cords, generally by calendering two material to combine them together firmly.

The arrangement of synthetic-tire-cord reinforcement layers is the core technology of ship launching airbag manufacturers, most of them are protected by patents. Top airbag factories are using the “enlacing method”, wrap synthetic-tire-cord layers in s specific way to form seamless framework of airbags.

Some factories are using the “sticking method” to make airbag skeleton, sticking synthetic-tire-cord reinforcement layers together with 90-degree angle, just like stitching a cylindrical pillow if you take sticking as stitching. Obviously, the sticking method is not as good as enlacing method for airbag performance and safety, but it can save material and cost so still some airbag manufacturers are using this outdated producing method. The below picture shows the difefrence of layers arrangement of airbags produced by two different methods.

The dimension change ratio is a good index to distinguish the airbags made by Enlacing or sticking method.

The airbag dimension change ratio of zero pressure and rated pressure less than 5% for airbags produced by true enlacing method.

The airbag dimension change ratio of zero pressure and rated pressure less than 5% for airbags produced by sticking method is bigger than 6% generally.

Item 5.1.3 (ISO 14409) Reinforcing Material

Asked by ISO 14409, the warp of Synthetic-tire -cords should be 90 cords per 100 mm in width, and the breaking strength shall be more than 205 N per cord.

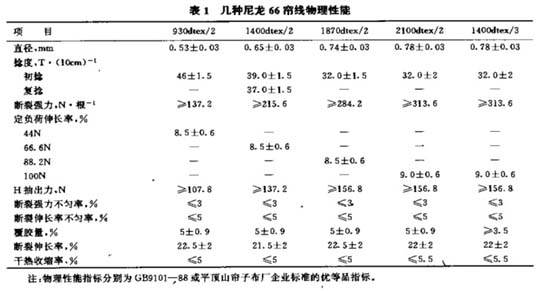

The comparison of different nylon 66 cords performance is listed below.

From table we can read both standard nylon 66 (1400 dtex/2) cords and nylon 66 (1400 dtex/3) cords meet this requirement but their performance have 50% difference.

Synthetic-tire-cords normally refer to nylon cords, which is the most expensive material in ship launching airbags. Then there are lots of tricks the airbag manufactures can play with such reinforcement materials.

Some airbag factories use polyester fiber instead of nylon cords to cut off the cost or use thin nylon cords to produce cheap airbags.

Qingdao Evergreen Maritime CO., LTD is the benchmarking enterprises in the industry. Let us take Evergreen ship launching airbags as a sample to see what is nylon cords are used in main stream good airbags. Evergreen Maritime are using nylon 66 (1400 dtex/3) cords for regular airbag manufacturing. Furthermore, the nylon cords will be pretreated to reduce surface tension before calendering with rubber sheets, in this way can ensure a good bonding of rubber sheets with cords. That is why Evergreen ship launching airbags have more than 5 times safety factor.

Item 6 (ISO 14409) Test of ship launching airbags

The ISO standard lists 5 items of ship launching airbags tests include gas tightness test, compression test, bearing capacity test, bursting test, compression-recovery test,

Gas tightness test and bearing capacity test are both asked to be carried out when airbags are filled with rated pressure. Minimum burst pressure is required to be at least 3 times of rated pressure.

For the method of ship launching airbags bursting test, the ISO 14409 only indicate “Fill the air bag with water until the air bag bursts.”. In fact, airbag factories should pay more attention to the safety problems of performing such bursting test. A remote-controlled airbag bursting test is recommended.

Reference: Evergreen airbag bursting test

Conclusion

ISO 14409 regulates basic requirements of ship launching airbags, some contents need to be enriched to guide airbag manufacturers and customers better for producing and using marine airbags.