Ship launching airbags

Five times safety coefficient

ISO 14409 certificated

Maximum size D3.5 mX L30 m

Lifespan 5-8 years

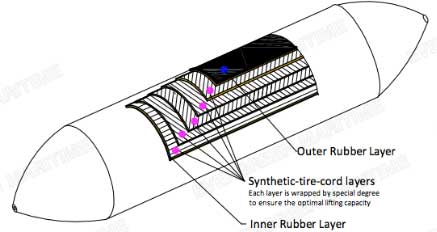

Ship Launching Airbags have been widely used to launch ships from land to water, such as for barge launching, cargo ship launching, tug boat launching.,etc. They consist of outer rubber layers, synthetic-cord-reinforced rubber layers, are kind of sausage-shaped pneumatic balloons. Ship launching airbag is invented by Chinese and can only be made in China up to now. The two ISO standards about ship launching airbags : ISO 14409:2011 Ships and marine technology — Ship launching air bags and ISO 17682 :2013 Ships and marine technology — Methodology for ship launching utilizing air bags are both drafted by Chinese airbag manufacturers.

Structure

- Outer rubber

The outer rubber layer that covers the outside of ship launching airbags protects the cord layers from abrasion and other external forces. This compound has sufficient tensile and tear strength to withstand any weather condition and hard usage.

- Synthetic-tyre-cord layer for reinforcement

There’re two types of synthetic-tire-cords used in Eversafe ship launching airbags to achieve best performance.

- End Fittings

Classification

- The standard specification of airbags.

You can choose the required diameter and effective length to meet your projects.

Diameter (D) : It’s from 0.8m to 2.0m.

Effective Length (EL) : It’s from 6m to 18m.

Total Length (TL) : It’s from 7m to 19.5m

The above specification only is our standard specification arrange. Other specification Ship Launching Airbags also can be supplied upon clients’ request.

- Standard number of layers

We define the number of layer, which means the number of Synthetic-tyre-cord layer, in order to confirm the Safety Working Pressure. Normally, Eversafe Airbags include 4, 5, 6, 7, 8 layers types. Other type is available upon clients’ request. - The material of Eversafe marine airbags

There’re two kinds of synthetic-tire-cord because of the different performance.

Advantages

- Best natural rubber ensure airbag’s preeminent quality .

- Deploys three strands synthetic-tire-cords with 31 kg breaking force.

- Patented enlacing manufacturing technique achieves no joint seam airbags

- Patented cone ends design eliminates safety problems

- We have higher demands of airbags, we use own produced airbags undertake projects.

Ultimate Guides to Ship Launching Airbags

History of ship launching airbags

The history of marine air bag dates back to 1990s. A Chinese ship repair and building shipyard launched a 60 DWT tank barge with marine airbags on January 20, 1981 and it is known as the first use of marine airbags. The invention of marine airbags was expected to develop a flexible, less limited ship launching method.

The first generation marine airbags employ rubber dipped canvases as reinforcement material and two cone-shaped ends are stuck to the chamber trunk. The canvases used for ship launching airbags are made of cotton or Polyester, whose breaking force and fatigue resistance performance limit airbags’ safety and performance. Thus only small vessels , hundreds tonnes ship can be launched with marine airbags.

Lots of reinforcement material have been tested in airbag production, at last polyhexamethylene adipamide (PA 66) became the main framework material of rubber airbags nowadays.The new material has fairly great improvement in performance of high temperature resistance, fatigue resistance and permanent deformation resistance.

Anyway in China still there are some ship launching factories, usually in small size, are using Polycaprolactam (PA 6) or Polyester in airbag production. By this the cost can reduce 20% or more compared with using PA66 that is why they sell airbags cheap.

Ship launching airbag structure

Sometime ship launching airbags are called pneumatic rollers or sausage balloons, they have sausage shape, cylinder body with two cone-shaped ends.

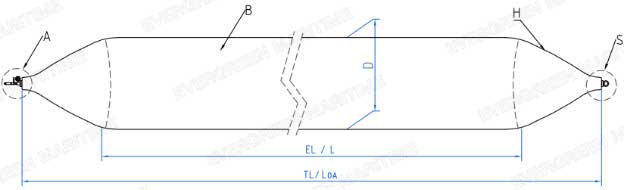

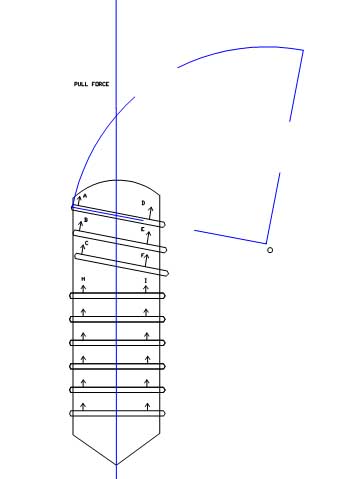

A. Safety air inlet system; B. Airbags Body; S: Air tightness swivel;

D. Diameter; Le. Effective Length; L/Loa. Total length

In perspective view, ship launching airbags look like this

A. An air bag is to be constructed of an outer rubber layer, multiple synthetic-tire-cord layers, and an inner rubber layers

B. When says layers of ship launching airbags, normally it means the reinforcement layers.

Ship launching airbag sizes

- Ship launching airbags are classified by diameters ,length and reinforcement layers.

- Available diameter of ship launching airbags: maximal 2.5 m

- Available length of ship launching airbags: maximal 25 m

- Available layers of ship launching airbags: standard airbag has 6 reinforcement layers, can increased to maximal 10 layers

Ship launching airbag burst testing

Airbag Burst testing is used to determine the absolute maximum pressure at which ship launching airbags will “burst” or fail catastrophically. It is the ultimate test method for the Ship Launching airbags’performance and safety.

- Airbag burst test is invaluable for airbag design engineers to assist with material selection, wall thickness, or component geometry, structure optimization etc. This test can be used to determine the pressure at which a component or assembly begins to plastically deform and its ultimate tensile strength, then help manufacturers to establish safety design margins.

- Identifying the maximum burst pressure is critical to decide the safety factor of ship launching airbags. Marine airbags usually are used in the open site and exposed to personnel, safety is always most concerned for both manufacturers and customers.

Evergreen Maritime conducts hydrostatic burst testing by using water to his marine airbags regularly by production lot or each time main material batch change to monitor the production and quality control. Burst testing is conducted using a plc controlled, monitored, and computer regulated test bench; featuring data acquisition at 50 Hz, calibrated pressure transducer, and protective safety features.

For more information of AIRBAG BURST TEST please refer :http://eversafemarine.net/burst-test-of-ship-launching-airbags/

How ship launching airbags are produced

- Material of ship launching airbags

Main material of ship launching airbags are framework material, rubber, chemical agents, hardware of ends. - Framework material are PA66 normally. Rubber include kinds of functional rubbers, include polychloroprene,styrene-butadiene rubber, ethylene propylene terpolymer, native rubber which are deployed in different layers of airbags.

- Big factories such as Evergreen Maritime, they have research labs for rubber formula, produce rubber sheets by themselves. Thus to ensure the quality and performance of ship launching airbags.

Procedure of marine airbag producing

- Step one: Making rubber sheets for different layers of airbags

Step two: Using coating calender to combine framework material with rubbers sheets then get the sheets called cords fabrics. - Step three: Forming. To make cords fabrics into airbags, there are two kinds of methods:

- Outdated one is sticking method. as the name indicates, all layers are sticking together like sticking a pillow. The connection of airbag body and two coned ends is weakest part of such airbags. Producing airbags by sticking method saves time and material thus some airbag factories are still using it.

- The mainstream of airbag producing method is enlacing technique. Layers are enlaced with a cross angle, between layers chemical are coated to enhance the bond. Airbags produced by this technique have better performance and safety compared with those made by sticking method.

- Step four: Vulcanization

When airbags forming is completed , airbags will be transported into vulcanizing tank for curing. After vulcanization airbags are ready for use.

Ship launching airbags price

The price of ship launching airbags is calculated by airbag surface area. Usually factories are using the cylinder surface area formula to calculate airbag surface area.

It means, if D represent airbag diameter, L means airbag flat length, P represents airbag layers number,

Then airbag surface area will be calculated as : S=πD(D+L)

Unit surface price of airbag is quite different for different factories, generally it is in the scope of USD 4 to USD 8 for each square meters.

Standards of ship launching airbags

There are two Chinese standards and two ISO standards for ship launching airbags production and using.

- CB/T 3837-1998 Technological Requirements for ship Upgrading or Launching Relying on Airbags (Shipbuilding Industry Standard, PRC)

- CB/T 3795-1996 / CB/T 3795-2009 Air bag for ship up to or down to launching way (Shipbuilding Industry Standard, PRC)

- ISO 14409: 2011 Ships and marine technology — Ship launching air bags

- ISO 17682:2013 Ships and marine technology — Methodology for ship launching utilizing air bags

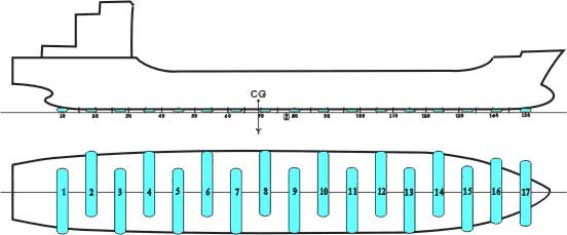

How to select marine airbags for ship launch project

Air bags diameter

- Airbag diameter should be bigger than heights of keel blocks under the ships. Normally if heights of keel block are less than 1 m , airbags with 1.5 m diameter should be selected. If keel block is about 1.2-1.5 m high , then 1.8 m or 2 m diameter airbags are good. This principle is same for ship launching and ship drydocking.

- If 1.5 m diameter airbags are enough for the project, no need to select bigger airbags.

- Big diameter marine airbags have lower working pressure compared with small diameter airbags.

Airbag length

- If possible the length of airbags should be longer than vessel width.

- If vessel width is more than 25 m, divide the width by 2 and plus 1-2 meters to decide airbag length. For example if ship width is 30 m, 16 m long airbags can be selected, they need to be staggered to support the vessel.

- If it is a super wide vessel, such as floating dry dock, may consider use three rows airbags to full support the vessel or two rows airbags for partly support.

Number of Airbag layers (plies)

- Six layers bags are suitable for most ship launching/docking projects.

- With more layers airbags’ performance and working pressure will increase but not proportional. Should consider the balance of pay and gain.

- When the project needs higher working pressure of airbags, may consider select airbags with more than 6 layers. For example, if a structure or vessel has limited bottom area can be supported by airbags and the object has big weight at the same time, so need airbags have high working pressure. At that time select airbags with more plies are reasonable.

- Increasing airbag quantity is better than purchase airbags with more plies.

- Using airbags properly is more effective than purchasing airbags with more plies.

Airbag quantity

How to decide airbags quantities for a ship launching or hauling project is not difficult. Even you are not a professional engineer, still can solve it by simple calculation.

- Calculate how much load airbags need to take.

- Figure out the length of ship bottom that can be supported by airbags.

- Figure out minimal spacing of airbags.

- Figure out the maximal allowable unsupported length of to the vessel

- Pick up a figure between result of step 3 and step four.

- Divide available bottom length by result of step five, then get the airbag quantity you need.

Different types of vessel may need to adjust the airbag quantity according to practical conditions.

Consult with a professional marine engineer who is experienced in ship launching or dry docking for airbag size and quantity selection is important anyway.

How to use marine airbags to launch a ship

Using marine airbags to launch a ship is neither a new idea nor new technique. In China people launched ships with marine airbags for more than 30 years. Accompanying with achievements of practice, the research of theory and launching calculation developed fast in recent ten years.

A general procedure of ship launching with airbags can be described as below:

- Set up holding system

Vessel need to be hold in position before the launching by holding system, which includes winches, wire ropes and pulleys. Winch should connect to ground anchors by welding or wire ropes.For some temporary launching, people can also crawler crane to hole the vessel instead of winch by which can save the construction of winch foundation. - Safety factor of holding system should be at least 1.5 .

- lift up vessel from keel blocks

Insert airbags between keel blocks, then inflating airbags to jack up vessel. Generally the vessel will be lifted up from one end to another, step by step. Once vessel bottom leaves from support blocks, those blocks will be removed.

- Adjusting before final launch

That adjustment includes adjusting airbag pressure and vessel position. Sometimes vessel is built far away from the water, before launching vessel needs to be moved down on slipway.

Pressures of ship launching Airbags need to be adjusted before the final launching according to practical conditions. All adjustments should be done base on the launching calculation.

- Final launch

Most airbag launching projects are free launch that means holding wire ropes will be removed to start the launching. To do so people can use the auto-release hook to release vessels or cut holding wire ropes by gas cutting. Even it is called free launch, the distance of vessel will travel in water will be calculated ahead to ensure safety.

If launch area is limited, people can use the control launching, releasing winch ropes to let vessel roll down into water slowly. Due to huge moment of vessel once it moves, the winch to control vessel’s movement speed must be big enough.

How to store ship launching airbags

- Ship launching airbags should be cleaned with fresh water and dried then powdered with french chalk (hydrated magnesium silicate) powder.

- Ship launching airbags should be stored in cool, dry sheltered place, kept away from chemicals, gasoline, solvent etc.

- Ship launching airbags can be piled for storing.

How to repair airbags

Please refer the link: http://eversafemarine.net/how-to-repair-a-hole-on-airbags/

Reviews from client

Evergreen Maritime offered us pneumatic rollers for a pump house structure launching. Their ship launching airbags are extremely versatile with good quality. The ongoing support enhances the operational capabilities. Eversafe Marine engineers are highly experienced in the use of airbags available to assist those companies not used the previously,with large or difficult launching.

—John Hamilton, P. Eng.

Manager, Projects

Oil & Gas and Power

Sherritt International Corporation

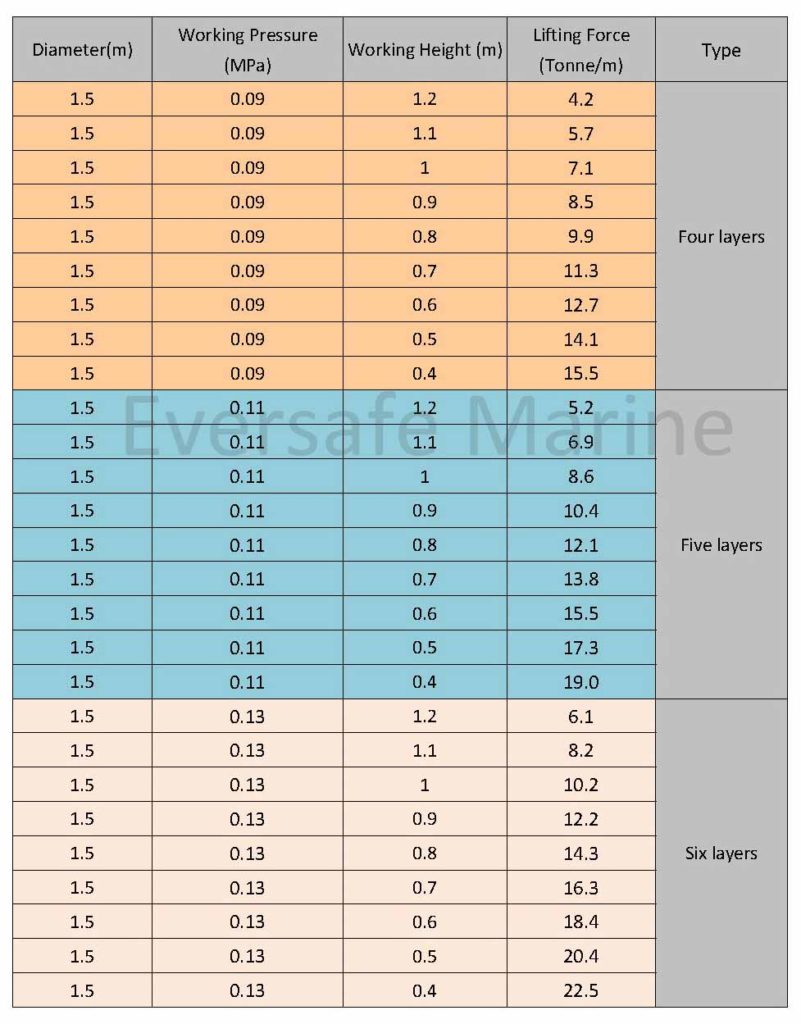

Performance of ship launching airbags

The performance table of airbags with other specifications are available upon request.

Q: Can marine airbags be reused? How many times it can be used?

A: Yes. Marine airbags surely can be used and for many times. Proper usage and good maintenance can prolong airbag’s lifespan. Generally speaking marine airbag has 5-8 years lifespan with proper maintenance.

Q: How can marine airbags make vessel takes a turn when they are used to move vessel?

A: Airbags have been used for heavy transportation for many years. In most applications the transported heavy often need to be turned around during forward move process.

The principle is same like vehicle takes a turn . When a 4-Wheeler/Car takes a turn, to enable it go through it smoothly, its ‘outer’ wheels need to turn faster than the ‘inner’ ones.

When people want to turn the vessel with airbags they will place the front airbags to be inclined. See below inllustration.

The front 3 pieces airbags are placed inclined, when they move forward they move like to go around a circle center. So the A\B\C three points’ speed is bigger than D\E\F. Since behind airbags are perpendicular to the vessel center line, the H and I points have same speed. So when vessel goes forward its front will turn right.

That is the basic principle of airbags turn vessel. In the practical operation people will pull forward or pull back vessel for some times to make an accurate turn. That is also the reason that we need to make airbags to be perpendicular to launching direction when we want to launch vessel in direct line.

Q: What is the maximum pressure of marine airbags?

A: Here we understand maximum pressure means maximum safe working pressure. The structure layers and diameter effect airbag’s maximum working pressure in fact. With more layers airbag can have higher working pressure, bigger diameter the lower pressure.

We have tested every type airbag’s bursting pressure so we know the pressure limit. Just to prevent from cribbing we won’t publish the data in public. Ask us in private you will get what you want.

Q: Why some Chinese made airbags are easy to burst?

A: Even people often call marine airbags as balloon they should be toy balloon. Good airbag manufacturer has strict quality control policy and completed test instruments to ensure airbag’s quality.

But in China there are some airbag factories, in fact they can not be called factory, workshop may be right , make low quality airbags. They have no idea of products quality but good at cost cutting . You get what you pay for. It is commonsense.

Q: Why our new bought airbag looks like used one? Some patch can be found on it.

New airbag or used one is easy to distinguish, if there are abrasions on airbag body then it is used one. But some new airbags can have patches.

In our company all airbags will be tested before delivery. If quality control people find there is any blemish of airbags they will ask technician to fix the problems. Generally the blemish is not a problem even not treated. We want to have our airbags the best performance so we patch some blemishes.

We know it is ugly to have patches on new airbags. But we ensure client the top quality of product then the beauty . Anyway we are improving manufacture technology to extinguish blemish of airbags.

Evergreen Maritime offered us pneumatic rollers for a pump house structure launching. Their ship launching airbags are extremely versatile with good quality. The ongoing support enhances the operational capabilities. Eversafe Marine engineers are highly experienced in the use of airbags available to assist those companies not used the previously,with large or difficult launching.

—John Hamilton, P. Eng.

Manager, Projects

Oil & Gas and Power

Sherritt International CorporatioN