Evergreen netless type foam filled fenders meet the most stringent quality and performance demands providing tough heavy-duty fendering systems for harbor, offshore and ship-to-ship applications.

Construction Features

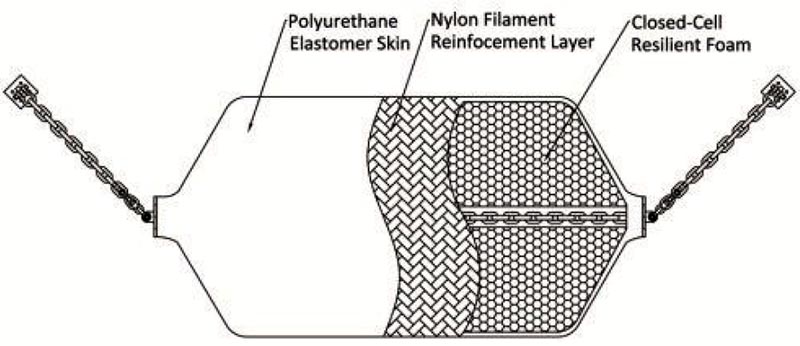

Completely filled fender shell with energy absorbing foam core of closed-cell cross-linked polyethylene foam. The foam core is homogeneous and of one piece fabricated construction .This resilient foam-filled construction provides an unsinkable fender body that permits high energy absorption with a relatively low reaction force compared to most other fendering systems.

- Evergreen foam filled fenders’ skin is constructed of a urethane elastomer which is reinforced with nylon filament in a continuous winding process. Meanwhile, multiple homogeneous layers increasing strength and additional reinforcement are applied as the transition layer. Special layers are applied to both ends where stresses are highest. This system enhances the ability of resisting to deflection and shearing force.

- Heavy duty internal chain connecting the end fittings is applied to transmit tensile loads through the fenders. (This will be equipped as per clients’ requirement.)

- The integral swivel end fittings provide secure point of attachment without obstructing, even when the fender is compressed. The fittings are constructed of top quality steel.

Advantages

- High Energy Absorption and Low Reaction Force

- Wide Range of Standard and Custom Sizes & Colors

- Tough, nylon filament reinforced polyurethane skin

- Unsinkable Design

- Easy Installation

- Hull Conforming

- Low Maintenance

- Burst Resistance

Performance Table of regular Foam fender

| Diameter x Length | Standard Capacity Foam Filled Fenders | ||||

| Metric | English | Energy Absorption at 60% deflection | Reaction Force at 60% deflection | ||

| (mm) | (ft) | (ft-kips) | (ton-m) | (kip) | (ton) |

| 700 x 1500 | 2.3 x 4.9 | 19 | 3 | 30 | 13 |

| 1000 x 1500 | 3.3 x 4.9 | 35 | 5 | 39 | 17 |

| 1000 x 2000 | 3.3 x 6.5 | 50 | 7 | 57 | 26 |

| 1200 x 2000 | 3.9 x 6.5 | 67 | 10 | 63 | 28 |

| 1350 x 2500 | 4.4 x 8.2 | 112 | 16 | 94 | 42 |

| 1500 x 3000 | 4.9 x 9.8 | 171 | 24 | 130 | 59 |

| 1700 x 3000 | 5.6 x 9.8 | 208 | 29 | 139 | 63 |

| 2000 x 3500 | 6.5 x 11.5 | 335 | 47 | 190 | 86 |

| 2000 x 4000 | 6.5 x 13.1 | 398 | 56 | 226 | 102 |

| 2000 x 4500 | 6.5 x 14.7 | 460 | 64 | 261 | 118 |

| 2500 x 4000 | 8.2 x 13.1 | 591 | 82 | 269 | 122 |

| 2500 x 5500 | 8.2 x 18.0 | 885 | 123 | 402 | 182 |

| 3000 x 6000 | 9.8 x 19.7 | 1365 | 189 | 516 | 234 |

| 3300 x 4500 | 10.8 x 14.7 | 1105 | 153 | 380 | 172 |

| 3300 x 6500 | 10.8 x 21.3 | 1786 | 248 | 614 | 279 |