Evergreen Marine set up domestic standard of netted and netless style foam filled marine fenders in the industry. Those fenders meet the most stringent quality and performance demands providing tough heavy-duty fendering systems for harbor, offshore and ship-to-ship applications.

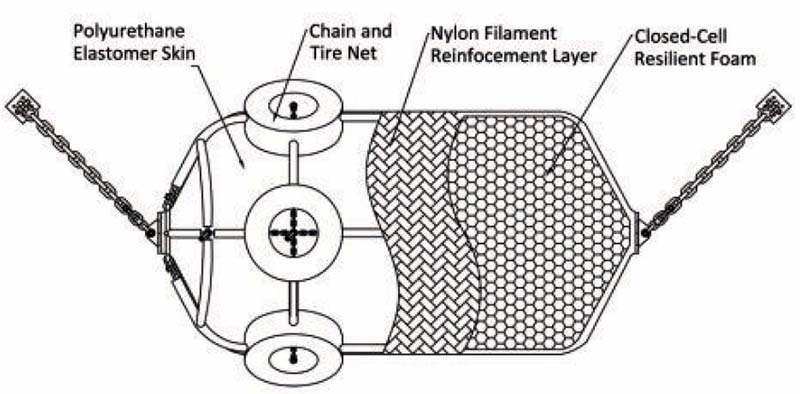

- A superior external chain and tire net, heavy-duty rubber tubing and chains that are connected at every intersection with a shackle. This is the key element in the Ever-Cushion marine fenders un-surpassed strength and resilience.

- The fender has a heat laminated 100% closed cell and resilient foam core that is energy absorbing and cannot be ruptured. This fabrication process uses no adhesives, which decomposes after time therefore making the Ever-Cushion™ superior in quality, durability and function. This resilient foam-filled construction provides an unsinkable fender body that permits high energy absorption with a relatively low reaction force compared to most other fendering systems.

- In order to enhance the performance of foam fenders, the Eversafe foam fenders skin is constructed of tough and thick nylon filament reinforced polyurethane skin. The skin also has a nylon tire cord applied in a helix pattern during the coating that embeds the filament into the skin. Special layers are applied to both ends where stresses are highest. This advanced process makes the foam fender skin extremely durable to all weather, forces and marine conditions.

- Various optional fitting designs are available for different requirement. The integral swivel end fittings provide secure point of attachment without obstructing, even when the fender is compressed. The fittings and accessories are constructed of top quality steel (HDG).

Standard size and performance

| Diameter x Length | Standard Netted Foam Fenders | ||||

| Metric | English | Energy Absorption at 60% deflection | Reaction Force at 60% deflection | ||

| (mm) | (ft) | (ft-kips) | (ton-m) | (kip) | (ton) |

| 1000 x 1500 | 3.3 x 4.9 | 33 | 5 | 47 | 21 |

| 1000 x 2000 | 3.3 x 6.6 | 48 | 7 | 67 | 30 |

| 1200 x 2000 | 3.9 x 6.6 | 64 | 9 | 76 | 34 |

| 1350 x 2500 | 4.4 x 8.2 | 103 | 14 | 109 | 49 |

| 1500 x 3000 | 4.9 x 9.8 | 155 | 21 | 146 | 66 |

| 1700 x 3000 | 5.6 x 9.8 | 196 | 27 | 162 | 73 |

| 2000 x 3500 | 6.6 x 11.5 | 317 | 44 | 222 | 101 |

| 2000 x 4000 | 6.6 x 13.1 | 371 | 51 | 259 | 117 |

| 2200 x 45000 | 7.2 x 14.8 | 500 | 69 | 321 | 146 |

| 2500 x 4000 | 8.2 x 13.1 | 541 | 75 | 305 | 138 |

| 2500 x 5500 | 8.2 x 18.0 | 294 | 110 | 447 | 203 |

| 3000 x 6000 | 9.8 x 19.7 | 1213 | 168 | 571 | 259 |

| 3300 x 4500 | 10.8 x 14.8 | 1007 | 139 | 430 | 195 |

| 3300 x 6500 | 10.8 x 21.3 | 1581 | 219 | 675 | 306 |

Fender Quality control

There is no ISO standard of foam filled fenders presently, we design the test methods according to USACE / NAVFAC / AFCESA demands.

- Fender Cyclic-Compression Test. Compress the fender along its diameter between two parallel flat plate surfaces to a compressed dimension of 40 percent of its original diameter. Repeat the compression and release cyclic loadings for a minimum of 10 full cycles of compression. Permanent deformation, cracking, or tearing of the fender skin, fender core, or end fittings shall constitute failure of this test.

- Fender Sustained-Load Test. Apply a rated compressive load and hold this load for 24 hours. Record load and deflection each hour. Immediately after release of the load, measure rebound of the fender. Continue to record fender rebound for 24 hours. Failure of the fender or foam core to rebound to 90 percent of its original diameter after 24 hours shall constitute failure of this test. If the foam core is not bonded to the skin of the fender, devise and execute a means for measuring rebound of the foam core and for measuring the void between the foam core and the skin. The maximum rate of compression per minute shall be 20 percent of the total reaction force at 60 percent compression. The full compression cycle, not including rebound, shall take a minimum of 5 minutes.

- Fender Pull-Through Test. Devise and perform a test which will measure the resistance of the end fittings and internal chain to pull through the longitudinal axis of the fender. Failure of the chain, end fittings, or skin to resist rated force of pull-through tension shall constitute failure of this test. After loading, evidence of permanent deformation, cracking, or tearing of the fender or end fittings shall also constitute failure of this test.

- Skin Thickness Core Test.